Understanding Packaging Blades: Essential Tools for Professionals

Packaging blades are vital components in various manufacturing and industrial settings. These specialized blades are designed to make precise cuts in materials that are often used for packaging products for shipping and storage. In this article, we will explore the significance of packaging blades, the different types available, factors to consider when selecting them, and the professional services that ensure their longevity and efficiency.

The Importance of Packaging Blades in Industry

In the world of manufacturing and production, the term “packaging” refers to the process of designing and producing containers for merchandise. Proper packaging not only protects the product but also enhances its appeal and facilitates logistics. Here is why packaging blades are crucial:

- Efficiency: Well-designed blades provide quick and accurate cuts, thereby increasing the production speed.

- Quality: The quality of the cut affects how well products are packaged and presented to consumers.

- Safety: Using the right blade ensures that operations are done safely, minimizing the risk of accidents.

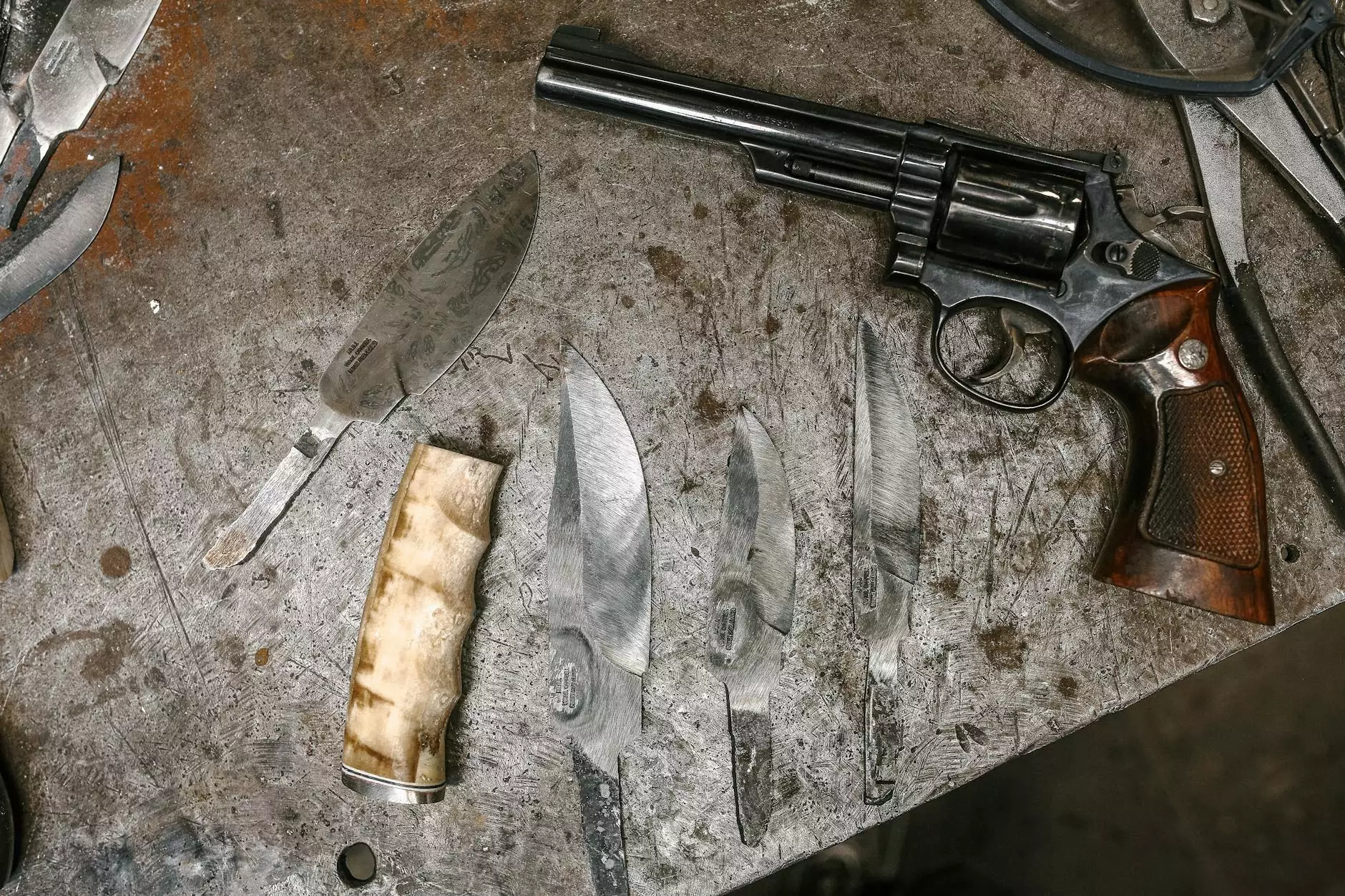

Types of Packaging Blades

When it comes to packaging blades, there is a wide array of types available to cater to different needs. Understanding these various types can assist businesses in making informed choices:

1. Straight Blades

Straight blades are often used for cutting through thick materials like cardboard or plastic. Their sharp edges allow for clean cuts, which are essential for quality packaging.

2. Serrated Blades

Serrated packaging blades are used for cutting softer materials like foam or certain types of plastic films. Their design allows them to grip the material, preventing slippage during cutting.

3. Utility Blades

Utility blades are versatile blades that can be used for various tasks. They are replaceable and easy to handle, which makes them popular in many work environments.

4. Specialty Blades

Some tasks require specialty blades that are engineered for specific applications, such as slicing, trimming, or scoring materials. These blades often have unique designs to suit specialized needs.

Choosing the Right Packaging Blade

Selecting the appropriate packaging blade can be daunting, given the numerous options available. Here are some crucial factors to consider:

Material of the Blade

The choice of material affects the durability and performance of the blade. Here are common materials:

- Stainless Steel: Resistant to corrosion, making it suitable for various environments.

- Carbon Steel: Known for its sharpness and edge retention but is more prone to rust.

- Ceramic: Offers excellent hardness but may be brittle.

Blade Thickness

Thickness can influence the strength and rigidity of the blade. Thicker blades are more robust but less flexible, while thinner blades may be able to navigate tighter curves but are more susceptible to breaking.

Cutting Technique

Understanding the cutting technique required for your tasks can determine the best blade. Some operations may need a more precise cut while others may require a straight, powerful slice. It’s essential to match the blade’s design to the daily tasks.

Professional Services for Blade Maintenance

To maintain the efficiency and extend the lifespan of packaging blades, professional sharpening and maintenance services are essential. This is where businesses like SZ Blade come into play.

Knife Sharpening Services

Professional knife sharpening services ensure that your packaging blades are always at their best. At SZ Blade, we offer specialized sharpening that caters specifically to packaging blades. This service includes:

- Precision Sharpening: Ensures that the cutting edge is restored to optimal sharpness.

- Custom Profiles: Tailoring the blade profile to meet specific cutting needs.

- Material Compatibility: Acknowledging and adapting to the materials used in production.

Safety Inspections

Regular checks conducted by trained professionals help in identifying wear and tear along with any potential safety issues. Maintaining a safe working environment is paramount.

Conclusion

In conclusion, packaging blades play a pivotal role in the efficiency and quality of manufacturing and packaging processes. Understanding the different types of blades, choosing the right one, and ensuring proper maintenance through professional services are all crucial steps to success in this field.

For businesses looking to enhance their operations, exploring high-quality packaging solutions and engaging reliable services such as those provided by SZ Blade can lead to improved performance and increased customer satisfaction.

Contact Us at SZ Blade

If you require expert advice on packaging blades or need professional knife sharpening services, don’t hesitate to reach out to our team. We specialize in providing tailored solutions that meet the unique demands of your business.

© 2023 SZ Blade. All rights reserved. Contact us for more information on our professional services.